WE PROVE BY ACTION

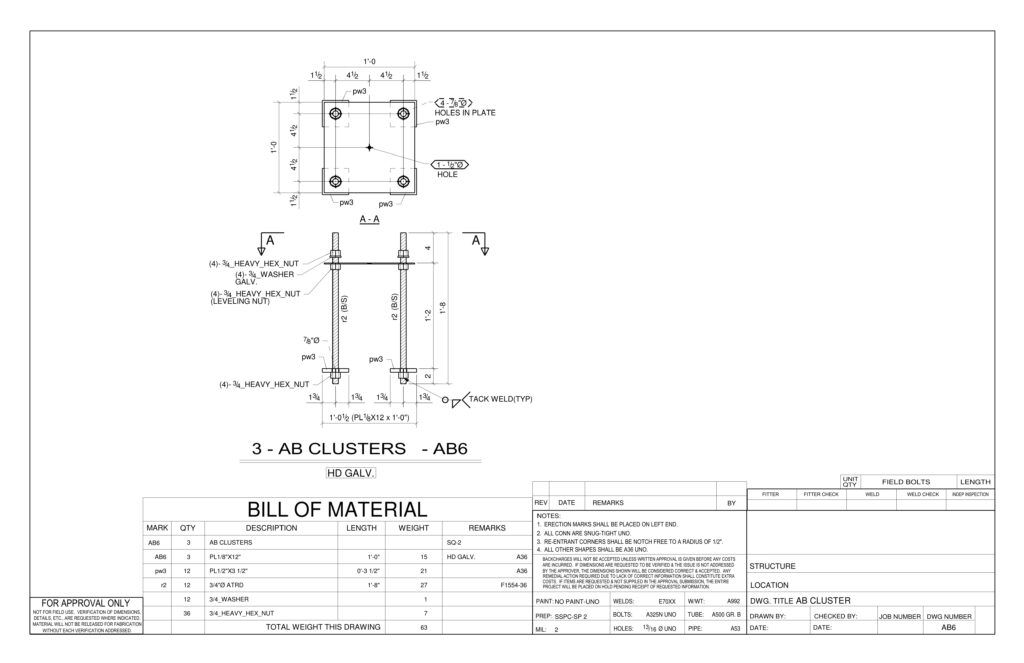

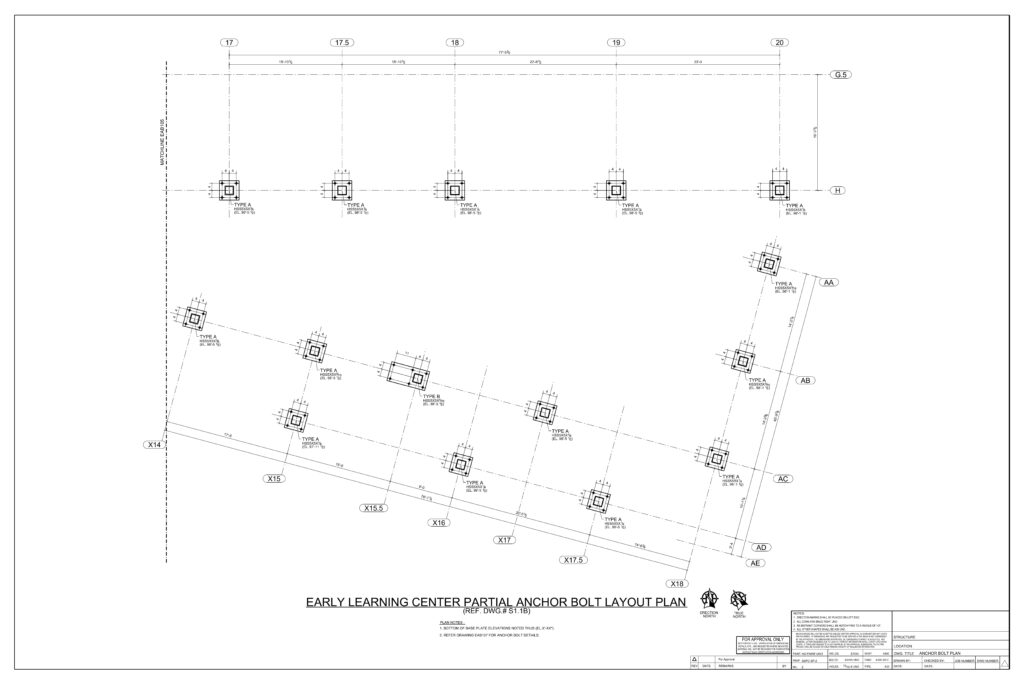

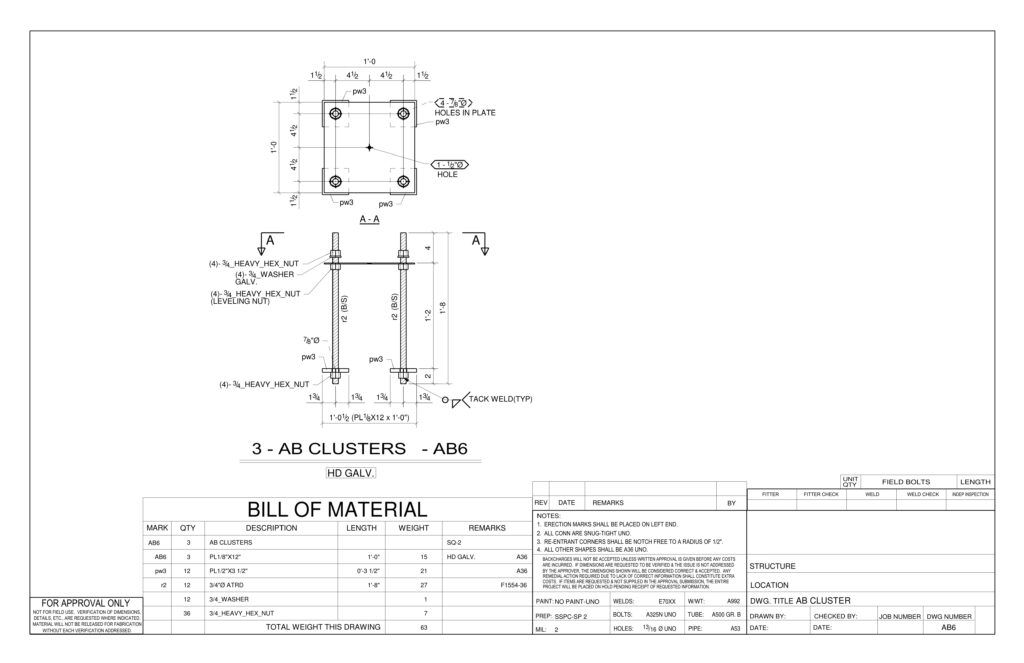

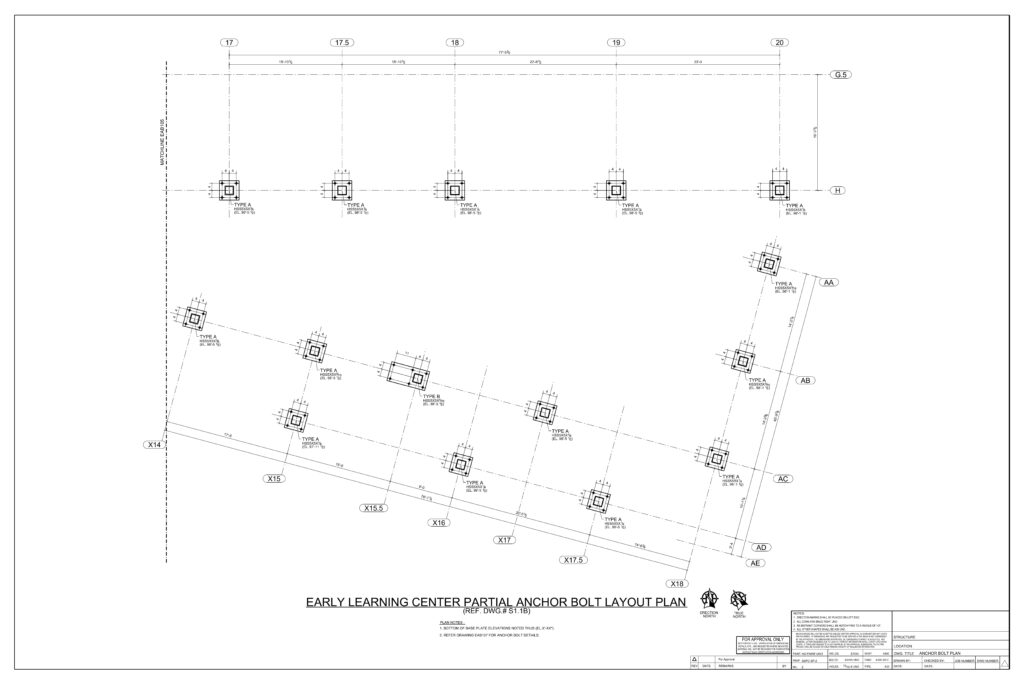

ANCHOR BOLT SAMPLE DRAWINGS

ANCHOR BOLT SAMPLE DRAWINGS

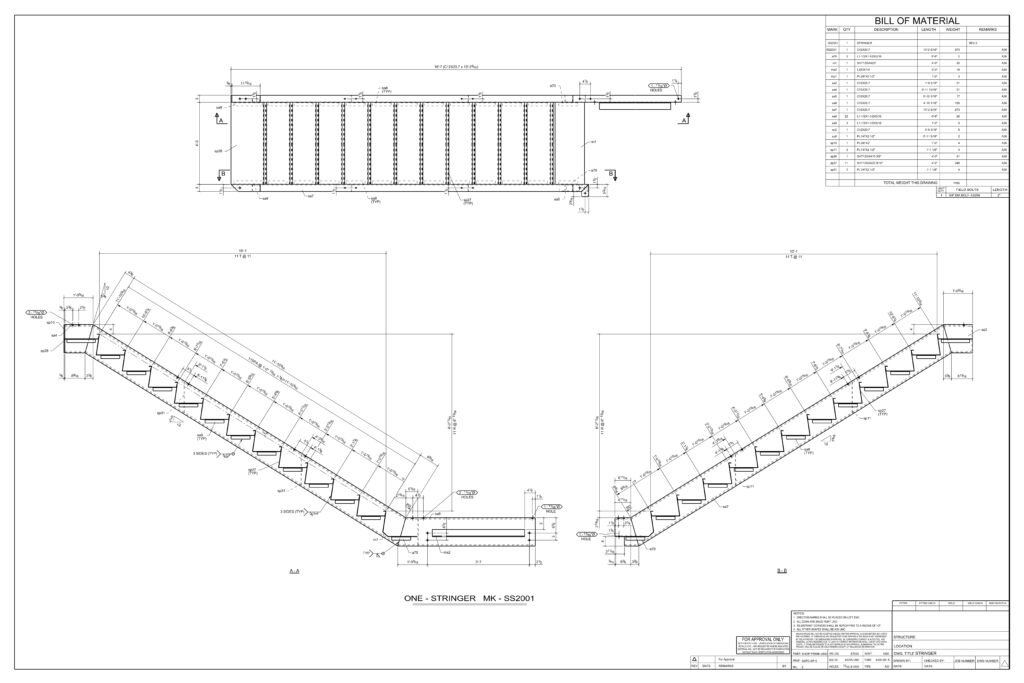

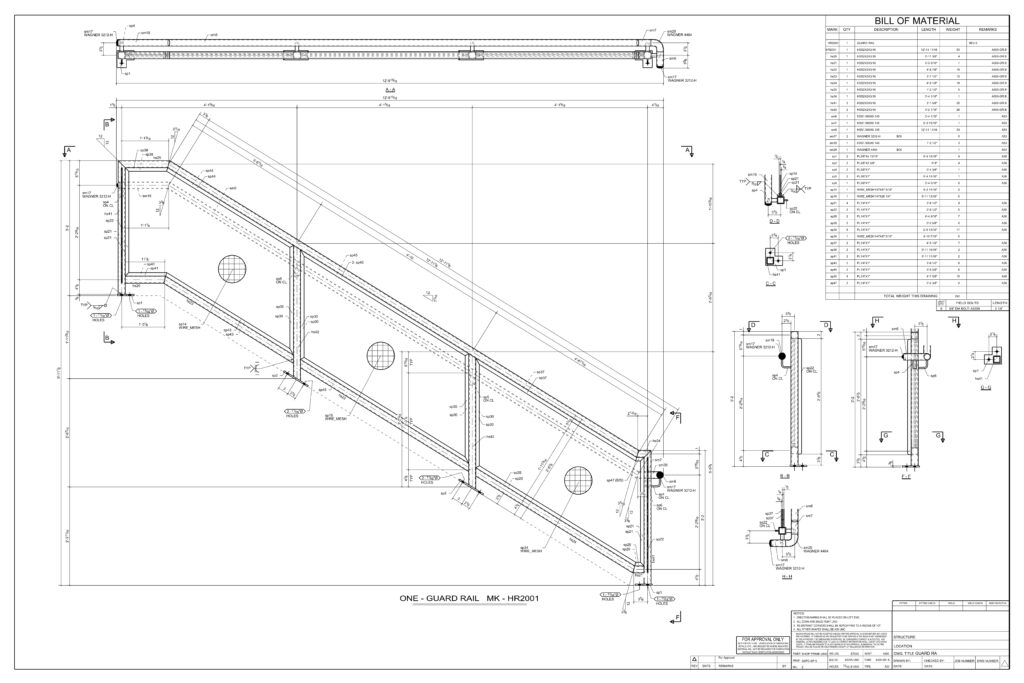

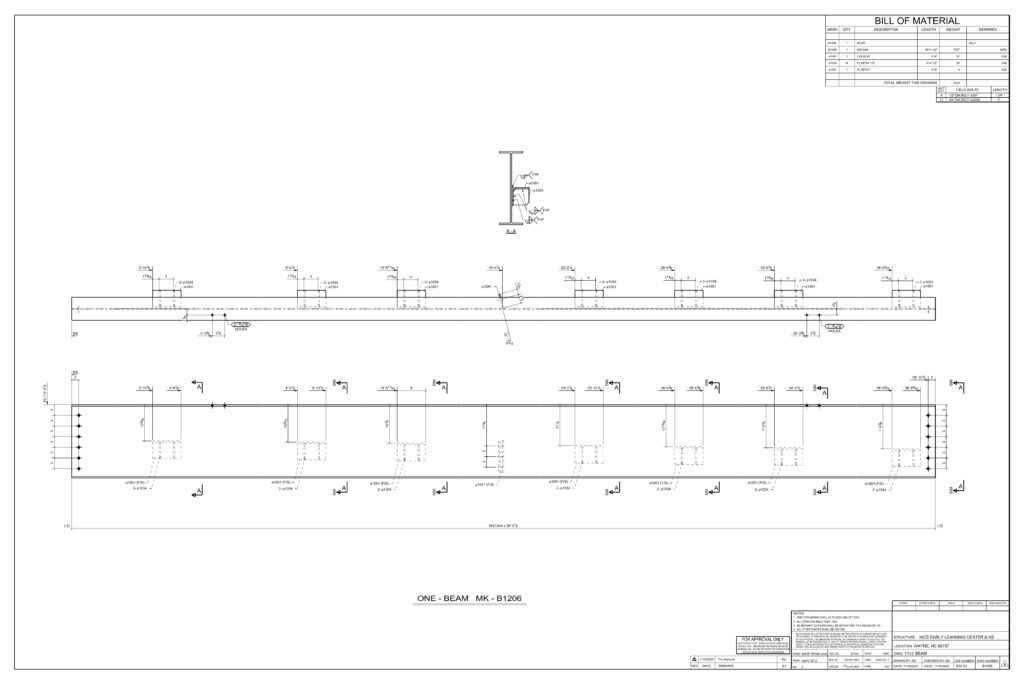

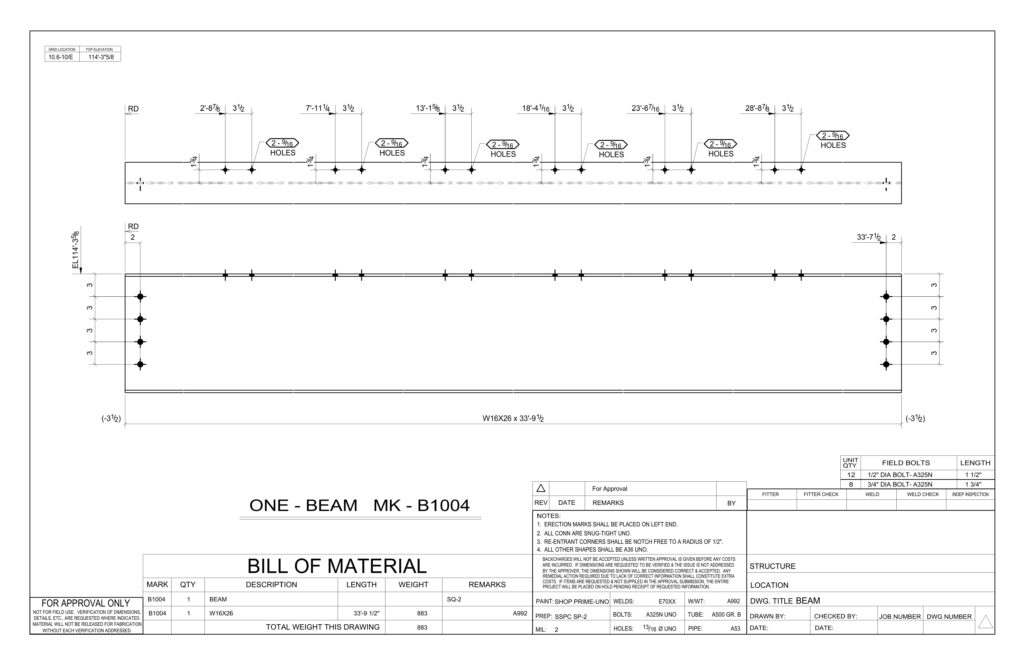

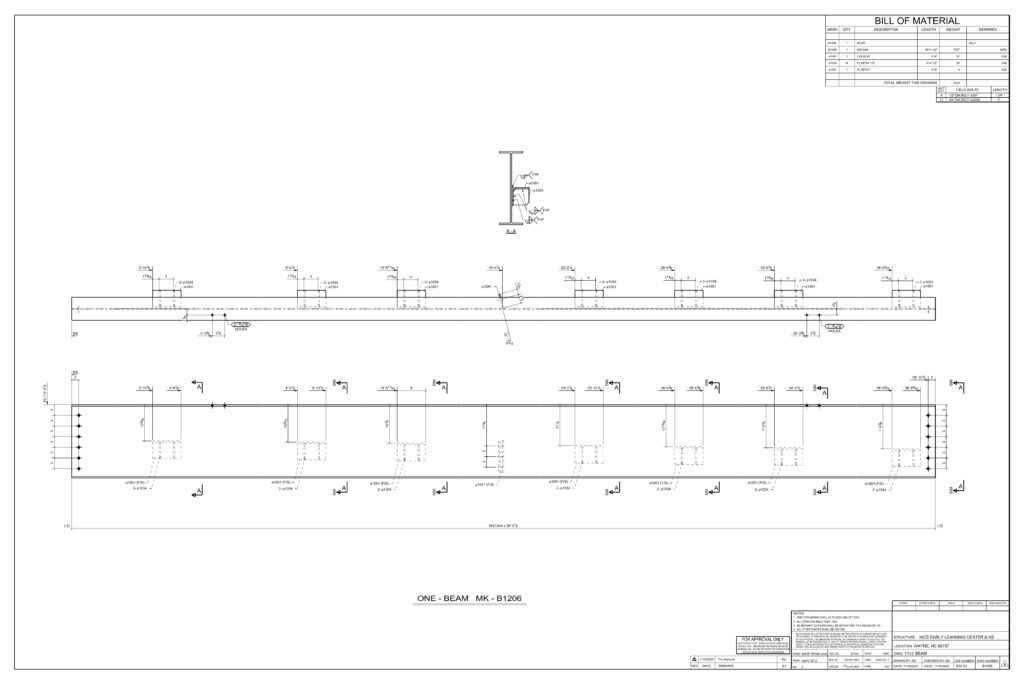

ERECTION SAMPLE DRAWINGS

ERECTION SAMPLE DRAWINGS

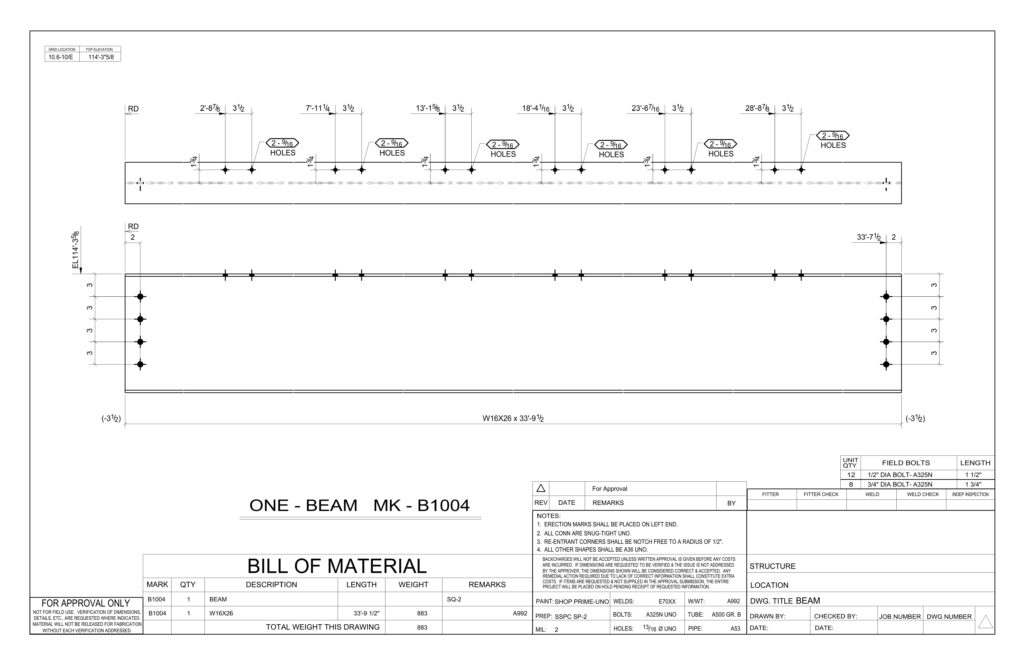

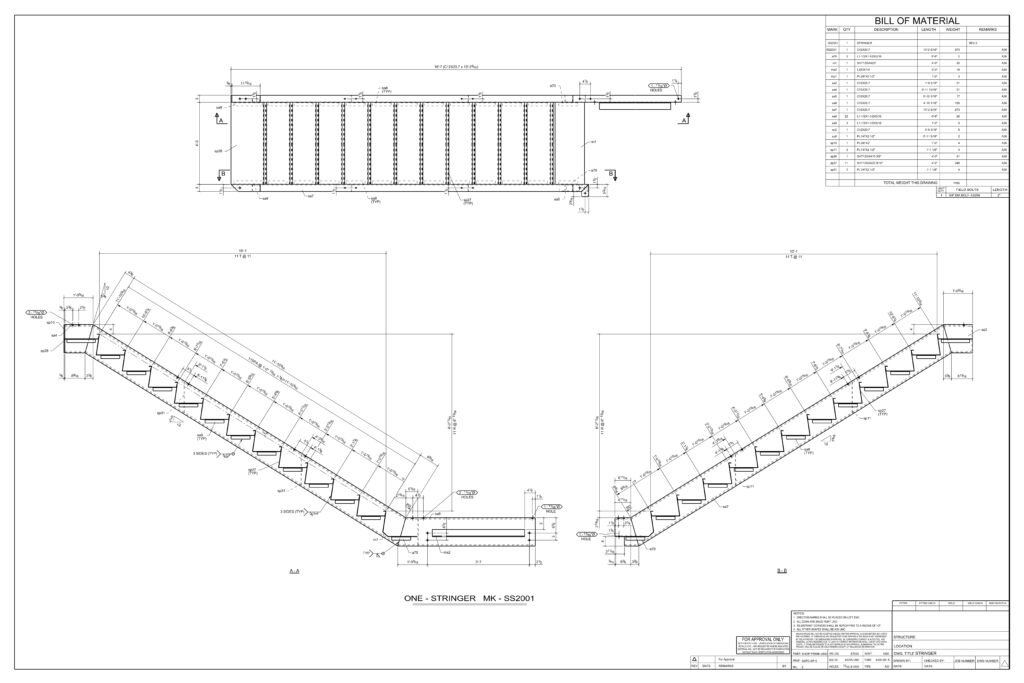

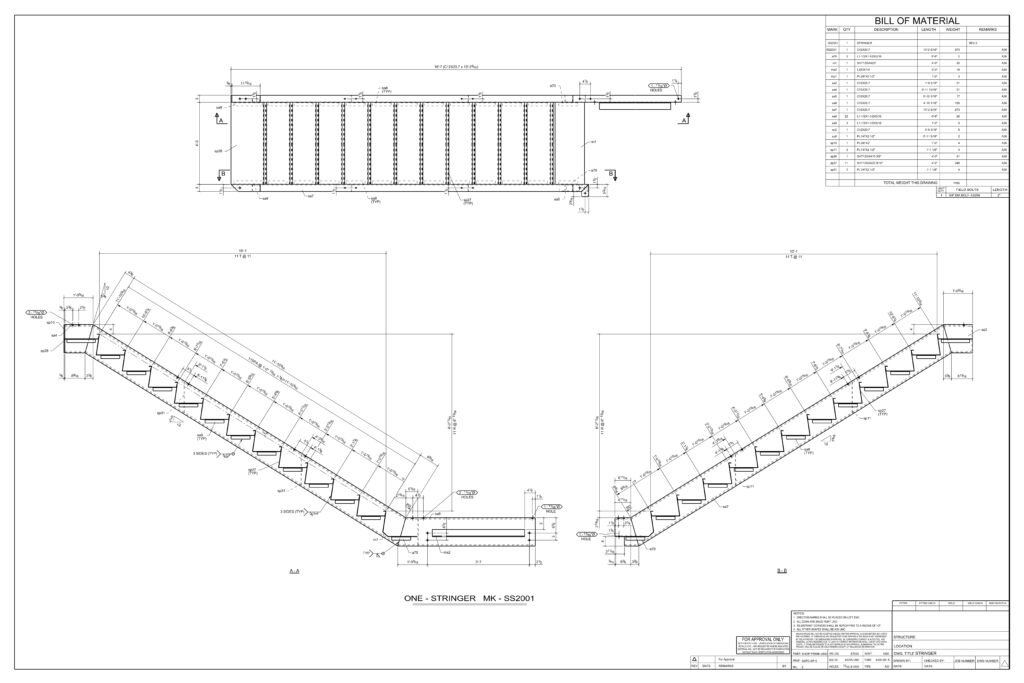

SHOP SAMPLE DRAWINGS

SHOP SAMPLE DRAWINGS

Anchor Bolt Drawing

Anchor Bolt Drawing

Erection Drawing

Erection Drawings

Shop Drawing

Shop Drawing

Questions & Answers

What services do you offer?

Structural Steel Detailing

Accurate 2D drawings & 3D models using Tekla Structures and AutoCAD.

Fabrication and erection drawings for beams, columns, bracings, etc.

Connection Design & Detailing

End plate, base plate, moment & shear connections.

According to AISC, BS, Eurocode, or client-specific standards.

Shop/Fabrication Drawings

Clear and detailed drawings for workshop fabrication.

Includes material lists, part marks, weld symbols, and notes.

Erection Drawings

Field-friendly plans showing how components fit together onsite.

Sequencing, part positioning, and crane-lift planning if needed.

BIM Modeling (Tekla Structures)

Clash-free 3D steel modeling integrated with BIM workflows.

IFC, DWG, and CNC file exports for coordination and fabrication.

Anchor Bolt Plans & Templates

Accurate anchor bolt layouts for foundations.

Templates and installation guides.

Material Take-Off (MTO)/BOQ

Detailed material lists for procurement and cost estimation.

Precast/Hybrid Structure Detailing (if applicable)

Tekla modeling and detailing for precast or mixed-material structures.

How do you approach a new project

Understanding Client Requirements

We begin by thoroughly reviewing architectural and structural drawings, project specifications, and client expectations. We clarify project scope, deadlines, and standards (AISC, BS, Eurocode, etc.).Kickoff & Coordination

We hold a kickoff meeting (virtual or in-person) to align with the client’s team. Any questions or missing info are addressed upfront to avoid rework.Modeling & Drafting

Using Tekla Structures and AutoCAD, we create a detailed 3D model of the structure. Every beam, column, connection, and bolt is precisely placed as per design intent.Internal Quality Checks

Our QA team reviews the model and drawings to ensure compliance, clash detection, and accuracy. We ensure fabrication drawings are error-free before submission.Client Review & Feedback

We share the model and initial drawings for review. Any feedback or required changes are incorporated promptly.Final Submission

Once approved, we deliver the full package: fabrication drawings, erection drawings, CNC files, and material lists — all formatted to your standards.Ongoing Support

We stay available throughout the fabrication and erection phases to provide updates, revisions, and support as needed

What is your project timeline?

Timelines can vary based on the size and complexity of the project. Simpler jobs are completed quickly, while larger or more customized projects may take more time. We tailor our workflow to each project’s needs, always aiming to deliver with precision and efficiency.

For urgent timelines, we’re happy to explore phased deliveries or other flexible solutions

How much do your services cost?

Pricing varies depending on the scope, complexity, and timeline of the project. Once we understand your specific requirements, we’ll be happy to provide a customized quote that suits your needs.

What platforms do you work with?

We primarily work with industry-leading software to ensure accuracy, efficiency, and seamless collaboration. Our core platforms include:

Tekla Structures – for 3D modeling and detailed steel connections

AutoCAD – for 2D drafting and drawing review

Revit & Navisworks (if applicable) – for BIM coordination and model integration

Bluebeam, PDF Editors, Excel – for markups, reports, and take-offs

We’re also flexible in adapting to your preferred file formats or workflows to ensure smooth collaboration.